油田污油泥处理新技术与传统技术对比阐述 (The comparison between the new technology and the traditional technology of oil field sludge treatment is expounded)

- 分类:技术文章

- 作者:

- 来源:

- 发布时间:2017-11-07

- 访问量:217

【概要描述】一、技术简介。当前全世界都共同面临着环境污染的大问题。空中以大气污染为重,地面以油田污染为重。自人类发现并开采油田以来就没有任何一项技术能够全面彻底解决油田污油泥污染问题,所有技术均有局限性,不能形成一个完整的处理体系而适应任何油田。

I. Technical introduction.

At present, the whole world is faced with the big problem of environmental pollution.

Air pollution in the air and oil field pollution on the ground.

Since the discovery and exploitation of oil fields, there has not been any technology that can completely and thoroughly solve the problem of oil mud pollution in oil fields. All technologies have limitations and cannot form a complete treatment system suitable for any oil field.

油田污油泥处理新技术与传统技术对比阐述 (The comparison between the new technology and the traditional technology of oil field sludge treatment is expounded)

【概要描述】一、技术简介。当前全世界都共同面临着环境污染的大问题。空中以大气污染为重,地面以油田污染为重。自人类发现并开采油田以来就没有任何一项技术能够全面彻底解决油田污油泥污染问题,所有技术均有局限性,不能形成一个完整的处理体系而适应任何油田。

I. Technical introduction.

At present, the whole world is faced with the big problem of environmental pollution.

Air pollution in the air and oil field pollution on the ground.

Since the discovery and exploitation of oil fields, there has not been any technology that can completely and thoroughly solve the problem of oil mud pollution in oil fields. All technologies have limitations and cannot form a complete treatment system suitable for any oil field.

- 分类:技术文章

- 作者:

- 来源:

- 发布时间:2017-11-07

- 访问量:217

一、 技术简介 Technology introduction

当前全世界都共同面临着环境污染的大问题。空中以大气污染为重,地面以油田污染为重。自人类发现并开采油田以来就没有任何一项技术能够全面彻底解决油田污油泥污染问题,所有技术均有局限性,不能形成一个完整的处理体系而适应任何油田。针对如此空白技术领域,发明人认为:在科学技术领域内一定会有一种技术能够实现本领域内技术人员的理想。八年,日日夜夜无数次的苦思冥想、设计、制造、实验,发明人终于解开了这道难题。下面就用传统的方法做对比,从而更好地诠释本发明技术的优越性和现实性。

At present, the whole world is faced with the big problem of environmental pollution. Air pollution in the air and oil field pollution on the ground. Since the discovery and exploitation of oil fields, there has not been any technology that can completely and thoroughly solve the problem of oil mud pollution in oil fields. All technologies have limitations and cannot form a complete treatment system suitable for any oil field. In view of such a blank field of technology, the inventor believes that there must be a technology in the field of science and technology can realize the ideal of the technical personnel in the field. Eight years, day and night countless times of hard thinking, design, manufacture, experiment, the inventor finally solved the problem. The following is to make a comparison with the traditional method, so as to better interpret the superiority and reality of the technology of the invention.

1、物理化学提取与回收 Physical and chemical extraction and recovery

(1)萃取分离法 Extraction separation

萃取分离法是国外研究并已成功应用的一种油田污泥处理方法。在此工艺中,来自油田污水处理系统的含油污泥,经过浮选处理后,污油泥可被分为三部分:回收水、尾泥、浮渣。处理后回收水中的悬浮物含量得到降低,其中的有机物含量很低,可回收到污水处理系统进行重新利用;尾泥主要由大颗粒的无机物质组成,其中有机物含量很低,可以压滤成饼后做填埋处理;分离出来的浮渣则集中了绝大部分的原油、有机物以及大部分的轻质悬浮物,另外还有部分水。浮渣进入萃取装置中进行处理,萃取分离出可直接利用的原油及有机物,而余下的泥水则返回到浮选装置继续处理。

Extractive separation is a method of oilfield sludge treatment which has been studied and applied successfully in foreign countries. In this process, the oily sludge from the oilfield sewage treatment system can be divided into three parts after flotation treatment: recovered water, tailings, and scum. After treatment, the content of suspended matter in the recovered water is reduced, and the organic matter content is very low, which can be recycled to the sewage treatment system for reuse. The tailmud is mainly composed of large particles of inorganic material, which has a low organic content. It can be compressed and filtered into cakes for landfill treatment.

The scum contains most of the oil, most of the organic matter, most of the lightweight suspended matter, and some of the water. The dross is processed in the extraction unit, and the crude oil and organic matter that can be directly used are extracted and separated, while the remaining muddy water is returned to the flotation unit for further treatment.

这种分离处理工艺能够解决油田含油污泥的环境污染问题,并为其它有机物含量高的污泥处理提供了一条可借鉴之路,将有机污染物质转变为可利用的资源,从而消除了污染,是油田环境保护的有效措施之一。但此方法存在的问题是流程长、工艺复杂、处理费用高,萃取后的泥水返回浮选装置后会使浮渣越来越多,多数会进入油里,形成再次沉降到系统里,所以还有待于进一步改进。

This separation and treatment process can solve the environmental pollution problem of oil-bearing sludge in oil field, and provide a reference for other sludge treatment with high organic content. It can transform organic pollutants into utilizable resources, thus eliminating pollution. It is one of the effective measures for environmental protection in oil field.However, the problem of this method is that the process is long, the process is complex, the treatment cost is high, the mud water after extraction will return to the flotation device will make more and more scum, most will enter the oil, the formation of the second settlement into the system, so it still needs to be further improved.

(2)热水洗涤法 Hot water washing

热水洗涤法是美国环保局处理含油污泥优先采用的方法。国内目前主要用于含油土壤的处理。其方法是通过热碱水溶液反复洗涤含油污泥,再通过气浮实施固液分离。一般洗涤温度控制在70°C,液固比2:1,洗涤时间20分钟,能够将含油量30%的土壤洗至残油率为0.3%。混合碱可采用廉价的无机碱和无机盐,也可选用廉价的洗衣粉等。该方法能量消耗低、费用不高。缺点是产量低、气浮后油含悬浮细泥和水分高、不能连续生产等,目前单纯以回收污油为处理目的的工艺在油田已较少采用。

Hot water washing is the EPA's preferred method for treating oily sludge. At present, it is mainly used for the treatment of oily soil in China. The method is to wash the oily sludge repeatedly by hot alkaline solution, and then separate the solid from the liquid by air floatation. Generally, the washing temperature is controlled at 70°C, the liquid-solid ratio is 2:1, and the washing time is 20 minutes. It can wash the soil with oil content of 30% to the residual oil rate of 0.3%. Mixed alkali can use cheap inorganic alkali and inorganic salt, but also choose cheap washing powder, etc. This method has low energy consumption and low cost. The disadvantages are low yield, high suspended fine mud and water content in the oil after air floatation, and no continuous production, etc. At present, the process solely for the purpose of recovery of dirty oil has been rarely used in oil fields.

(3)化学破乳回收法 Chemical demulsification recovery method

采用化学破乳-热洗-机械三相离心分离技术来进行含油污泥的处理,原油可以回收利用,水相可重复利用,固相达标后可进行掩埋处理。机械三相分离出的水回用于含油污泥处理中,不仅可降低提取剂和破乳剂的用量,减少排污量,还可降低污泥处理的成本。该技术直接脱水回收燃料油,也可加工轻质油,可作为炼油厂含油污泥处置技术。缺点是三相分离机分离出的固相很难达标、水相虽可利用但还会有多余的外排、三相分离需加入絮凝剂,目前应用效果不佳。

Chemical demulsification - hot washing - mechanical three-phase centrifugal separation technology is adopted to treat oily sludge. The crude oil can be recycled, the water phase can be reused, and the solid phase can be buried after reaching the standard. The water separated by mechanical three-phase can be used in the treatment of oily sludge, which can not only reduce the amount of extractant and demulsifier, reduce the amount of sewage discharge, but also reduce the cost of sludge treatment. This technology can directly dehydrate and recycle fuel oil, and can also process light oil. It can be used as oily sludge disposal technology in oil refinery. Disadvantages are that the solid phase separated by the three-phase separator is difficult to reach the standard, although the water phase can be used, there will be redundant discharge, three-phase separation needs to add flocculant, the current application effect is not good.

(4)固液分离法 Solid liquid separation method

一般油田联合站产生的含油污泥含油量达10%以上,据油田工作经验,含油大于6%即有回收价值。实验证实,对于含油污泥通过掺入一定比例的水以后,投加无机混凝剂或有机高分子絮凝剂,在一定增温措施下可进行污油回收。在回收处理过程中,机械脱水是其关键技术,只有实现“水清、泥干、泥净、油纯”,才能显著减少后续处理的费用。另外提高固体回收率和减少泥饼含水率对降低含油污泥处理的总成本也具有重要意义,如泥饼含水从85%降至50%时,体积可减至前者的2/3,可大大节约运输及后处理费用。因此处理过程中应把好机械脱水关。缺点是加入絮凝剂泥饼里含油一定超标,泥净的目的无法达到,目前技术不成熟。

In general, the oil content of oily sludge produced by oilfield combined station is more than 10%. According to oilfield work experience, the oil content is more than 6%, which has the value of recovery. The experiment proved that the oily sludge could be recovered by adding inorganic coagulant or organic macromolecule flocculant after mixing a certain proportion of water. In the process of recycling, mechanical dehydration is the key technology, only to achieve "water clean, mud dry, mud clean, oil pure", can significantly reduce the cost of subsequent treatment. In addition, it is of great significance to reduce the total cost of oily sludge treatment to improve the solid recovery rate and reduce the moisture content of sludge cake. For example, when the water content of sludge cake is reduced from 85% to 50%, the volume of sludge cake can be reduced to 2/3 of the former, which can greatly save transportation and post-treatment costs. Therefore, the processing process should be good mechanical dehydration. The disadvantage is that the oil in the mud cake added with flocculant must exceed the standard, and the purpose of mud net cannot be achieved, and the current technology is not mature.

(5)浓缩干化法 Concentration drying method

浓缩干化法是一种传统的污泥处理工艺,主要是通过自然沉降去除污泥颗粒间隙中的水,这部分水一般占污泥含水的70%左右,通过浓缩处理可以使含水率降到95%左右,然后将浓缩后的污泥自然风干、填埋。该工艺的优点是基建投资和运转费用少,操作简单,因此国内前些年大多数油田采用该工艺处理含油污泥。该工艺的主要缺点是:(1)需要占用大面积的土地;(2)由于受油田环境气候的影响,工作环境不稳定;(3)干化场地卫生条件差;(4)当污泥的颗粒细小、粘度大、沉降和过滤性能较差时,很难使其干化;(5)含油污泥难达标,非环保处理。

Concentration and drying method is a traditional sludge treatment process. It mainly removes water in the gap between sludge particles through natural sedimentation, which generally accounts for about 70% of the water content of sludge. The water content can be reduced to about 95% through concentration treatment, and then the concentrated sludge is naturally air-dried and buried.

The advantage of this process is less capital investment and operation cost, simple operation, so the majority of domestic oil fields in the past few years to use this process to treat oily sludge.

The main disadvantages of this process are :

(1) it needs to occupy a large area of land;

(2) The working environment is unstable due to the influence of the environment and climate of the oil field;

(3) Poor sanitary conditions in the drying site;

(4) it is difficult to dry the sludge when it has fine particles, high viscosity, poor settling and filtration performance;

(5) oily sludge is difficult to reach the standard and is not environmentally friendly.

(6)热处理和热解吸技术 Heat treatment and thermal desorption technology

热处理和热解吸技术是上世纪90年代初国外迅速发展并获得应用的工艺。主要有Heue:等开发的包含低温(107-204°C)-高温(357-510°C )、加热蒸发-冷凝步骤的含油污泥处理工艺。该热解吸工艺是在一个装有密钢叶片转子的反应器中,把污泥从299°C加热到399°C,并通入蒸汽,使烃类在复杂的水合和裂化反应器中分离,并使泥渣达到直接填埋的要求。在路易斯安那炼油厂投产的热解吸装置,把含水50%的污物用钢带输送到密闭的温度分布为121-954°C的干燥装置内,年处理泥饼1400t;,可回收300t油和120t可燃气。缺点是成本极高、产量低不能量产。

Heat treatment and thermal desorption technology are rapidly developed and applied abroad in the early 1990s. It mainly includes the oily sludge treatment process developed by Heue: et al., which includes low temperature (107-204°C)- high temperature (357-510°C), heating evaporation-condensation steps. The thermal desorption process involves heating the sludge from 299°C to 399°C in a reactor equipped with a dense steel vane rotor. Steam is introduced to separate the hydrocarbons in a complex hydration and cracking reactor, and the sludge meets the requirements for direct landfill. The thermal desorption unit put into operation at the Louisiana refinery transmits 50% water content of sewage to a sealed drying unit with a temperature distribution of 121 °C to 954°C on a steel strip, treating 1,400 tons of mud cake per year. can recover 300t oil and 120t combustible gas. The disadvantage is that the cost is extremely high, the yield is low and the energy is not produced.

2、无害化处理方法 Harmless treatment method

(1)固化处理 Curing processing

固化处理是将含油污泥固化或包容在惰性固化基料中的一种无害化处理过程,以便于运输、利用或处理。这种处理方法能够较大程度地减少含油污泥中的有害离子和有机物对土壤的侵蚀和沥滤,从而减少对环境的影响和危害。缺点是固化剂会在未来若干年风华而后患无穷。

Curing treatment is a harmless treatment process in which oily sludge is solidified or contained in an inert curing base material in order to facilitate transportation, utilization or treatment. This treatment method can greatly reduce the erosion and leaching of soil by harmful ions and organic matter in oily sludge, thus reducing the impact and harm to the environment. The disadvantage is that curing agent will be in the next few years and endless problems.

(2)脱水焚烧处理 ) dehydration and incineration treatment

我国绝大多数炼油厂都建有污泥焚烧装置,对于含油污泥焚烧前应经过污泥脱水,处理过程为:将含油污泥放入污泥浓缩罐,同时适当加温(约60°C ),并投加絮凝剂,经搅拌、重力沉降后进行分层切水,再经过设备脱水、干燥等工艺,将泥饼送至焚烧炉进行焚烧,温度为800-850°C,经30分钟焚烧完毕,再对剩余灰渣做进一步的处理。焚烧法的优点是污泥经焚烧后,污泥中多种有害物几乎全部除去,减少了对环境的危害,缺点是焚烧过程中易产生二次污染,同时由于污泥没有得到充分利用而浪费了资源,要使污油泥燃烧需加入助燃剂,成本高。

Most refineries have the sludge incineration plant in our country, should pass before for oily sludge incineration of sludge dewatering, process is: put the oily sludge in sludge thickening tank, at the same time, the appropriate heating (60 ° C), and dosing flocculants, layered cut after classics agitate, gravity sedimentation water, after equipment of dehydration, drying process, the mud cake sent to the incinerator to burn, the temperature is 800-850 ° C, after 30 minutes after burning, the remaining ash again for further processing. The advantage of incineration method is that after sludge is incinerated, a variety of harmful substances in the sludge are almost completely removed, reducing the harm to the environment. The disadvantage is that secondary pollution is easy to occur in the incineration process. At the same time, because the sludge has not been fully utilized and the resources are wasted.

(3)微波处理技术 Microwave processing technology

利用微波可对含油污泥进行处理。微波热效应的特点是加热速度快、反应灵敏、加热均匀、效率高、选择性好。利用微波的特性对含油污泥进行干化和脱水,使污泥中的油水乳状液破乳分离,实现油、水、渣三相的分离和资源化利用,国内外均已开展了相关的研究工作。缺点是加热成本高、分离离不开机械,只是改变了加热方式而已。

Oily sludge can be treated by microwave. Microwave thermal effect is characterized by fast heating speed, sensitive reaction, uniform heating, high efficiency and good selectivity. The characteristics of microwave were used to dry and dehydrate oily sludge, so that the oil-water emulsion in the sludge could be demulsified and separated, and the separation and resource utilization of oil, water and residue could be realized. The disadvantage is that the heating cost is high, the separation is inseparable from the machinery, but the heating mode is changed.

3、生物降解技术 Biodegradation technology

含油污泥生物降解技术具有节约能源、投资少、运行费用低等优点,目前受到国内外的普遍关注和重视。含油污泥的特征污染物是石油烃类在自然条件下石油烃类可发生生物降解而达到逐渐自净,但降解过程非常缓慢,若能优化某些环境条件则可大大提高烃类的生物降解速度。这些环境条件包括营养物含量及比例、氧气含量环境PH值、湿度和温度等。据此,目前比较流行的生物降解技术有地耕法、堆肥处理法及生物反应器法。

Oily sludge biodegradation technology has many advantages, such as energy saving, low investment and low operating cost, and has been widely paid attention to at home and abroad. The characteristic pollutant of oily sludge is petroleum hydrocarbons. Under natural conditions, petroleum hydrocarbons can be biodegraded and gradually self-purified, but the degradation process is very slow. If some environmental conditions can be optimized, the biodegradation speed of hydrocarbons can be greatly improved. These environmental conditions include nutrient content and ratio, oxygen content, environmental pH, humidity and temperature, etc. Therefore, at present, the more popular biodegradation techniques include soil tillage, composting and bioreactor.

(1)上地耕作法 Upland tillage

采用土地耕作法处理含油污泥,一般都要投加肥料以平衡土壤中的C:N:P比,并调节土壤湿度及PH值以优化烃类的生物降解条件,要翻耕土壤使之充氧并使烃类在土壤中混合均匀。地耕法处理含油污泥的最大优点在于:它是通过天然过程将石油烃转化为无害的土壤成份,运行,nm费用低。但地耕法的净化过程较慢,不适用冬季较长的地区,而且生物难以降解的烃类(主要是高分子蜡及沥青质)易残留在农田中。

In the treatment of oily sludge by land cultivation, fertilizer should be added to balance the C: N: P ratio in the soil, and the soil moisture and pH value should be adjusted to optimize the biodegradation conditions of hydrocarbons. The soil should be ploughed to oxygenate and make the hydrocarbon mixed evenly in the soil.

The greatest advantage of soil tillage in treating oily sludge is that it converts petroleum hydrocarbons into harmless soil components through a natural process, and the operating cost of NM is low. However, the purification process of soil tillage is slow, it is not suitable for areas with long winters, and biodegradable hydrocarbons (mainly polymer wax and asphaltene) are easy to remain in farmland.

(2)堆肥法 Compost method

该方法采用垃圾堆肥处理的原理,将油泥放入堆肥池中,加入一定的营养物质,从底部不断通入空气,并保持一定温度和湿度,让微生物分解油泥中的有机物,达到去除油的目的。

The method adopts the principle of garbage composting treatment, put the sludge into the compost pool, add a certain amount of nutrients, constantly pass into the air from the bottom, and maintain a certain temperature and humidity, let the microorganisms decompose the organic matter in the sludge, to achieve the purpose of removing oil.

(3)生物反应器处理 Bioreactor treatment

在生物反应器中可利用微生物的降解作用实现破乳、絮凝、油水分离和分离出的污水中的有机物的降解。其核心部分为,通过高效的针对石油有机物细菌的作用,将含油污泥中的有机物降解为水和二氧化碳。处理分为厌氧和好氧两个阶段,在厌氧阶段,通过厌氧发酵降解难降解的有机大分子,同时,通过生物的破乳作用,将含油污泥中大量存在的乳化油进行破乳,并通过厌氧罐上部的收油装置将含油污泥中的大部分油回收。好氧阶段,将厌氧部分没有降解的有机物进一步降解。在好氧阶段之后是沉淀罐,悬浮物将在此沉淀下来,并且再回流到厌氧罐,污泥中没有降解完全的有机物将再经过厌氧发酵降解,回流同时又将沉淀下来的细菌回收进厌氧罐,增加生物处理的细菌量。生物降解技术目前多用于海滩污染、陆地输油管道泄漏的环境净化处理,处理油田大量污油泥还不能全面应用,同时也浪费资源。

In the bioreactor, the degradation of microorganisms can be used to achieve demulsification, flocculation, oil and water separation and the degradation of organic matter in the separated sewage. At its core, it degrades organic matter in oily sludge into water and carbon dioxide by highly effective targeting of petroleum organic bacteria. The treatment is divided into two stages, anaerobic and aerobic. In the anaerobic stage, the refractory organic macromolecules are degraded through anaerobic fermentation. At the same time, the emulsified oil, which is abundant in the oily sludge, is demulsified through biological demulsification, and most of the oil in the oily sludge is recovered through the oil collecting device at the upper part of the anaerobic tank. In the aerobic stage, the organic matter that has not been degraded in the anaerobic part is further degraded. After the aerobic stage is the precipitation tank, where the suspended matter will be precipitated and then returned to the anaerobic tank. The organic matter in the sludge that has not been completely degraded will be degraded by anaerobic fermentation. At the same time, the precipitated bacteria will be recovered into the anaerobic tank to increase the amount of bacteria in biological treatment. At present, biodegradation technology is mostly used for environmental purification treatment of beach pollution and land oil pipeline leakage, but it can not be fully applied to deal with a large amount of oil sludge in oil fields, and it also wastes resources.

4、莫尼亚公司的污油泥处理专利技术主要内容和基本思路

The main content and basic idea of the patent technology of sludge treatment of molniya company

专利污油泥卧螺离心机

Patented decanter centrifuge with oily sludge

(1)基本思路 ) Basic ideas

油泥虽然对环境危害较大,但是同时也是宝贵的油气次资源,因此在对油泥进行处理的过程中,也应该将其综合利用。莫尼亚公司专利技术是目前世界上最先进的最有效、最可行的处理方法,无论是从设备造价还是从操作技术简单易懂、生产成本和处理效果都能体现出较高性价比。

Although sludge is harmful to the environment, it is also a precious oil and gas resource, so it should be comprehensively utilized in the process of sludge treatment.

Molniya's patented technology is the most advanced and effective and feasible treatment method in the world. Whether it is from the cost of the equipment or the operation technology is simple and easy to understand, the production cost and the treatment effect can reflect the high cost performance.

莫尼亚公司对油田油泥处理方法的研究基本思路是:在认真研究污油泥处理技术与设备的基础上,坚信污油泥处理会有更好的方法,更好地设备,经多年研究、实验于是发明了当今最行之有效的技术与设备方案,能够实现对污油、污水和污油泥进行全方位净化,并达到国家环保要求和量产效果。最终目的是将技术成果应用到油田污油泥和机械废弃污油处理工作中,以提高经济和社会效益。

Molniya company research on oil field oil sludge treatment methods of the basic idea is: sewage sludge treatment technology and equipment in a careful study on the basis of the sewage sludge treatment can have a better way, better equipment, after years of research, experiment and so invented the most effective technologies and equipment solutions, can achieve the dirty oil, sewage sludge and sludge purification of all, and meet the national requirements of environmental protection and production effect. The ultimate purpose is to apply the technical achievements to the treatment of oilfield sludge and machinery waste sludge in order to improve economic and social benefits.

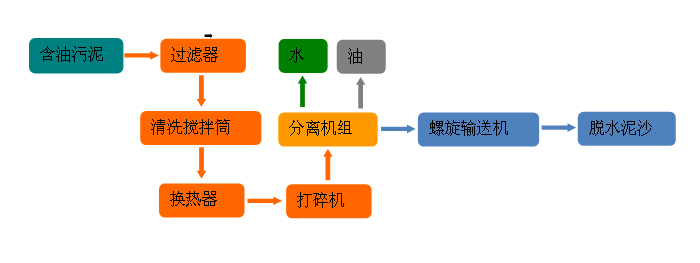

(2)具体的技术原理如下简述:莫尼亚公司发明的污油泥处理专利卧式离心机和污油泥处理专利新工艺,突破了污油泥处理有质量无产量,有产量无质量的世界性难题。其原理是利用专利高速离心机(非普通离心机)产生的巨大的离心力场,在离心力场的作用下,由于油和水的比重不同,于是比重较大的水就将比重相对较小的油从泥沙表面上置换出来,在经过特殊结构设计的离心机将污油泥里的油分离出来并自动收集外排,同时不受油水含量比例限制。污水进入普通污水卧螺离心机将泥分离出来外排,水进入水处理系统深度处理。在此污油泥处理过程中排序工艺和配套十分重要,该技术被我公司申请为发明专利技术。

The specific technical principle is briefly described as follows: the patented horizontal centrifuge and patented new process of sludge treatment invented by Molniya Company has broken through the worldwide problem of quality without yield and yield without quality in sludge treatment. Its principle is to use the patent high speed centrifuge (not ordinary centrifuge) produced by the centrifugal force field, under the action of centrifugal force field, because the proportion of oil and water is different, and the proportion of the larger water will be a relatively small proportion of oil out of the mud on the surface displacement, after special structure design of centrifuge to isolate the oil in the sewage sludge and automatically collect outside, without being limited by the oil and water content ratio at the same time. The sewage enters the ordinary sewage decanter centrifuge to separate the mud and discharge it, and the water enters the water treatment system for advanced treatment. Sorting technology and supporting equipment are very important in the process of sludge treatment. This technology has been applied as the invention patent technology by our company.

(3)技术参数 Technical parameters

污油泥调质后泥沙含量不大于 10% The sediment content after the sludge conditioning is not more than 10%

油水比例 不限 The proportion of oil and water is unlimited

处理后的泥沙含油 小于 2% The treated sediment contains less than 2% oil

处理后的油里含水 小于 0.3~1.0% The treated oil contains less than 0.3~1.0% water

处理后的水里含油 (污水去除泥饼后) 100~1000ppm Oil in the treated water (after the sewage mud cake removal) 100~1000ppm

5、含油污泥主要处理方法优缺点与莫尼亚专利技术比较表

Comparison table of advantages and disadvantages of main treatment methods of oily sludge and Monya patent technology

|

序号 No. |

处理方法 processing method |

适用范围 application |

优点 advantage |

缺点 disadvantage |

|

1 |

简单处置 simple dispose |

各类含油污泥 all kinds of oily mud |

简单易行 easy to do |

污染环境,不能回收原油 pollute and cannot recycle |

|

2 |

物理化学处理 physicochemical treatment |

含量在5~8%以上的含油污泥 oil sludge containing more than 5-8% |

回收原油, recovering crude oil,comprehensive utilization |

需处理装置,需加入化学药剂,仍有污水,废渣排放,处理费用较高 need deal with device,add chemical agent,sewage,waste residue discharge,cost is high. |

|

3 |

生物处理 biological treatment |

各类含油污泥 all kinds of oily sludge |

节省能源,无需化学药剂 save energy and no chemicals |

处理周期长,不能回收原油,适合处理季节有限制等 processing cycle is long,cannot recycle crude oil,suitable processing seasons is limited |

|

4 |

焚烧处理 incineration |

含油量在5~8%以下的含油污泥及含有害有机物的污泥 oil content in 5-8%below the oily sludge and sludge containing harmful organic matter |

有害有机物处理彻底 handle the harmful organic matter thoroughly |

需焚烧装置,通常需加入助燃燃料,有废气排放,不能回收原油 incinerator require,usually require add combustion-supporting fuel,exhaust emissions and cannot recover crude oil |

|

5 |

作燃料、制砖 for fuel, for bricks |

各类含油污泥 all kinds of sludge |

综合利用,较易实行 comprehensive utilization,easier to implement |

不能回收原油,有废气排放 can not recover crude oil,exhaust emissions |

|

6 |

莫尼亚专利技术 Molniya patented technology |

污油泥、老化油、含油浮渣、含油污水等 dirt sludge,aging oil,oily scum,oily sewage etc. |

纯物理法、环保达标、量产、费用低、收油率达99% pure physical method,environmental protection standards,mass production,low cost,oily recovery rate up to 99% |

|

6、 莫尼亚专利技术对比优势 Comparative advantage of Molniya patented technology:

1、 在污泥脱油阶段无需添加化学破乳剂、表面活性剂等化学药剂就可达到分离效果,因此可以大大减少处理成本更能避免因添加化学药剂而造成二次污染。(化学破乳剂通常需要80~400元/吨调质后物料)

In the sludge deoiling stage without adding chemical demulsifiers, surfactants and other chemical agents can achieve the separation effect, so it can greatly reduce the treatment cost and avoid the secondary pollution caused by adding chemical agents.

(Chemical demulsifier usually needs 80~400 yuan/ton of quenching and tempering materials)

2、 国际首创一次性分离后泥饼含油率低于2%。(国际传统工艺分离后的泥饼含油在10~30% 之间)

The oil content of the mud cake after one-time separation is less than 2%.

(The oil content of mud cake separated by international traditional process is between 10~30%)

3、 设备产量高,能够形成工业化量产,目前可设计每套撬装设备在2~25吨/小时生产能力,工厂化设计能力在30~300吨/小时的能力。

High equipment output, can form the industrial mass production, can design each set of skid-mounted equipment in 2~25 tons/hour production capacity, factory design capacity in 30~300 tons/hour capacity.

4、 自动化程度高,配备中央控制系统,可实现PLC自动化全程控制生产。

High degree of automation, equipped with a central control system, can achieve PLC automatic whole process control production.

莫尼亚污油泥处理专利工艺图

Monia sludge treatment patent process drawing

7、 结束语 conclusion

综上所述,国家治理污染迫在眉睫,能够发明一项新技术并迅速转化为生产力,即是政府的职责也是企业的责任。莫尼亚处理油田污油泥专利技术能够有效的实现给地球一片绿色,还社会一份能源的理想,希望能够得到政府的重视和广大致力于环保事业的有识之士的关注,为早日创造良好的社会效益和经济效益而发挥其应有的作用!

To sum up, it is urgent for the country to control pollution. It is the responsibility of both the government and enterprises to invent a new technology and quickly transform it into productive forces. Monya processing oil field sludge patent technology can effectively achieve a green to the earth, but also a social energy ideal, hope to get the attention of the government and the general commitment to the cause of environmental protection people of insight, as soon as possible to create good social and economic benefits and play its due role!

扫二维码用手机看

南京莫尼亚离心机科技发展有限公司

联系人: 陈永欣 18013325617

徐锋 18013035617

售后服务: 赵士波 18013344029

电话/传真:025-58474011

邮箱: molniya@126.com

网址:www.njmoniya.cn

公司地址:江苏省南京市六合区竹镇工业园凌峰路71号

General Sales Agent for Iran, Iraq and Syria:

Company: ROYESH BEDONE MAX.LTD

Contact: Mr. GHASEM AMANI

Telephone number: 0098 912 111 2893

Mail box: robimaxfactory@gmail.com

- 手机版 莫尼亚 -