Products

产品展示

成套设备现场图片 scene pictures of complete equipment

一、技术参数 Technical parameters

(一)设备参数 The equipment parameters

1、处理能力: 1、3、5、10、15、20吨/小时

Processing capacity: 1, 3, 5, 10, 15, 20 tons/hour

2、物料含固率: 10~20%

Solid content of material: 10 ~ 20%

3、物料含油率:小于 70%

Oil content of materials: less than 70%

4、加热温度: ℃ 40~70

Heating temperature: 40 ~ 70 ℃

5、室外温度:℃ -5~40

Outdoor temperature: -5 ~ 40 ℃

6、蒸汽锅炉:产气量180 ℃ 0.2~3吨/小时

steam boiler: gas production 180 ℃ 0.2 ~ 3 tons/hour

7、总功率配备: 30~200千瓦

Total power: 30 ~ 200 kW

(二)处理后参数 Post-processing paramete

1、泥中含油率: 1~3%

Oil content in mud: 1 ~ 3%

2、油中含水: 1~5%

Water in oil: 1 ~ 5%

3、油中含泥沙:小于 0.1%

Sediment in oil: less than 0.1%

4、水中含油: 小于 1000PPM

Oil in water: less than 1000PPM

5、减量率 70~90%以上

The reduction rate is over 70 ~ 90%

二、设备列表 The equipment list

|

序号 serial number |

名称 name |

型号 Model |

规格 specifications |

数量 quantity |

生产厂家 |

备注 remark |

|

1 |

LW型特种污油泥卧螺离心机 LW type special type sludge horizontal screw centrifuge |

LW250; LW420;LW450;LW500;LW550;LW650 |

Q=1;3;5;10;15;20m3/h Q(沉渣sediment)≤0.1~0.2;0.3~0.6;0.5~1.0;1.0~1.5;2.0~4.0m3/h |

1台 |

莫尼亚 Molniya |

|

|

2 |

处理模块 Processing module |

|

根据实际处理量设计模块的数量和规格 Design module quantity and specification according to actual processing capacity |

1~4个 |

莫尼亚 Molniya |

|

|

3 |

LW型污水卧螺离心机 LW model sewage horizontal screw |

LW360、450、500、550、650 |

Q=5~30m3/h Q(沉渣 sediment)≤1.0~6.0m3/h |

1台 |

莫尼亚 Molniya |

|

|

4 |

加热搅拌罐 Heating mixing tank |

2~5m3 |

|

2个 |

莫尼亚 Molniya |

|

|

5 |

过滤器 The filter |

10~30m3 |

|

2个 |

莫尼亚 Molniya |

|

|

6 |

加药箱 Add medicine cabinet |

1~2m3 |

|

1个 |

莫尼亚 Molniya |

|

|

7 |

螺旋输送器 Screw conveyor |

3~8m3 |

|

1个 |

|

|

|

8 |

电器控制柜 Electric control cabinet |

|

|

2~5个 |

莫尼亚 Molniya |

|

|

9 |

管道混合器及自清洗系统 Pipeline mixer and self-cleaning system |

|

|

1台 |

莫尼亚 Molniya |

|

|

10 |

空压机 Air compressor |

根据实际需要配置 Configure according to actual needs |

根据实际需要配置 Configure according to actual needs |

1台 |

|

|

|

11 |

各种阀、泵、管线、传感器等 Various valves, pumps, pipelines, sensors, etc |

根据实际需要配置 Configure according to actual needs |

根据实际需要配置 Configure according to actual needs |

若干 some |

|

均分布在各个模块上 They are distributed on each module |

三、技术说明 Technical specifications

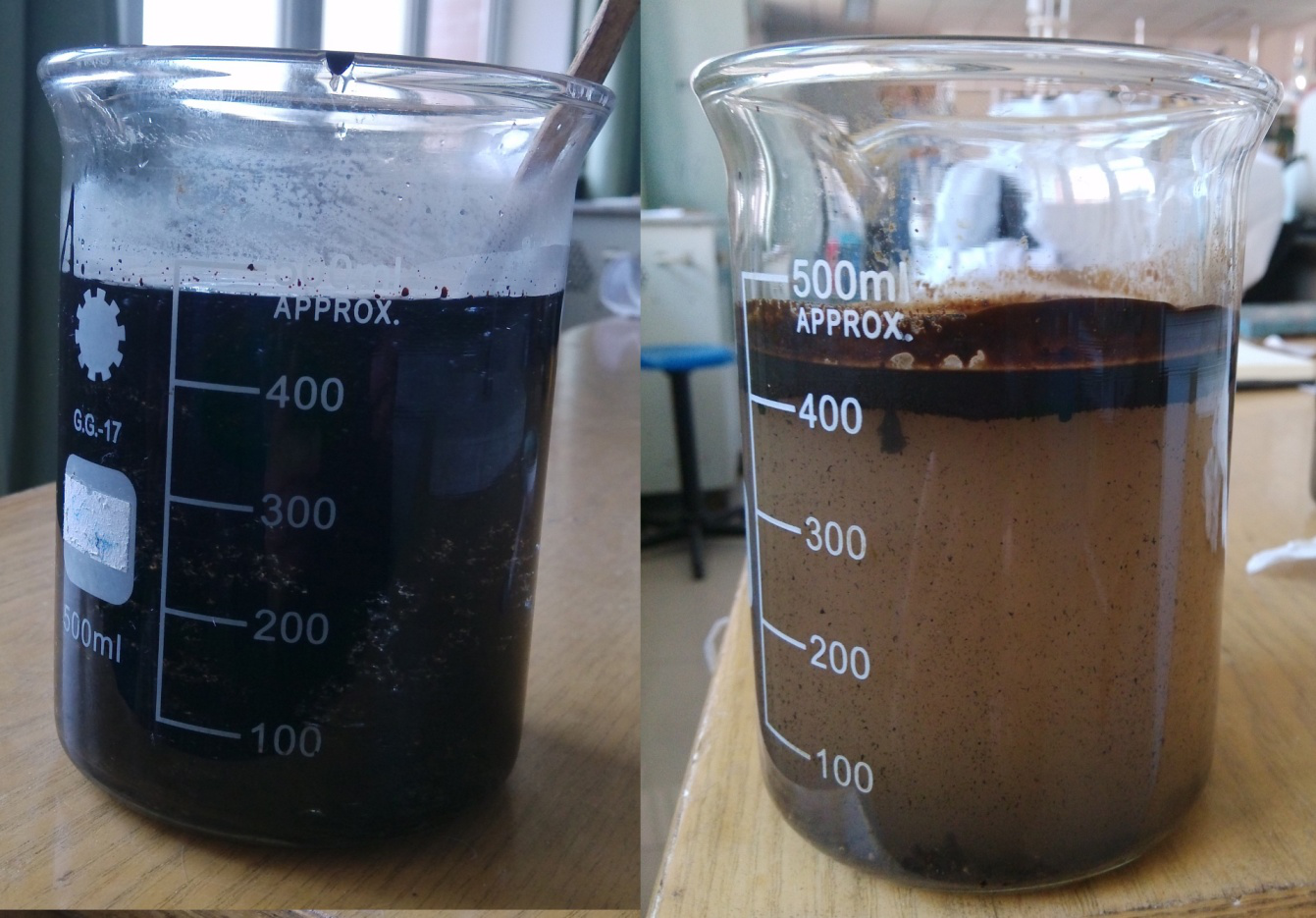

1、调质清洗技术 Tempering and cleaning technology

通过投加药剂并辅以加热、蒸洗、气浮、超声波、机械分散、减粘等调质及清洗手段,调整固体粒子群的性状和排列状态,使其中粘度大的吸附油解吸和破乳使之适合脱水。此技术为已获国家发明专利。

The properties and arrangement state of solid particle swarm can be adjusted by adding agents, supplemented by heating, steaming, air flotation, ultrasonic wave, mechanical dispersion, viscosity reduction and other conditioning and cleaning means, so that the viscous adsorption oil desorption and demulsification make it suitable for dehydration.This technology has been the national invention patent.

2、分离技术 Separation technology

利用专利高速卧式离心机产生的巨大离心力,在强大的离心力场的作用下,因为油和水的比重不同,比重较大的水将比重相对较小的吸附在泥沙表面上的油基团会置换出来,在经过特殊结构设计的卧式离心机,将置换出来的油隔离出来并自动收集外排。污水进入普通污水卧螺离心机将泥饼分离出来并外排,水进入水处理系统根据需要进行深度处理。

Large centrifugal force generated by patent high-speed horizontal centrifuge in strong under the action of centrifugal force field, because the proportion of oil and water, different proportion of large water adsorption in the sediment will be relatively small proportion of oil-base group on the surface displacement, after special structure design of horizontal centrifuge, will replace the oil isolated and automatically collect outside.Sewage will be separated into the common sewage horizontal screw centrifuge mud cake and discharged, water into the water treatment system for in-depth treatment according to the need.

3、脱水装置 Dehydration unit

含聚合物、硫化物成份的污泥分离而研究开发的新型高科技产品,是连续过滤及深度脱水的设备,它具有连续操作,生产能力大(一次干泥排放量可达4~5吨),操作维修方便、运行成本低等特点。新型过滤脱水技术是消化吸收国外先进技术上自主研发的新型固液分离设备。

The new high-tech product is a continuous filtration and deep dehydration equipment, which has the characteristics of continuous operation, large production capacity (the discharge volume of dry mud can reach 4~5 tons), easy operation and maintenance, low operating cost and so on.The new filtration and dehydration technology is a new solid-liquid separation equipment independently developed in digestion and absorption foreign advanced technology.

4、药剂技术 Pharmaceutical technology

破乳混凝剂属于无机高分子接枝共聚物,分子量较高,化学结构独特;在水中溶解后,能同时发挥粒子间吸附架桥与电中和作用,将废水中乳化油、 胶体凝聚而分离沉淀;具有优异的除油、脱色及COD的降低效果,一次性完成破乳同混凝过程。该产品操作简单,无需重复酸碱调整,可直接处理,提升处理效能。无机固化絮沉剂集破胶、絮凝、沉淀、改善泥层的固化性与一体,保证水质更清,保证泥饼的脱水效果。

Demulsifying coagulant belongs to inorganic polymer graft copolymer with high molecular weight and unique chemical structure.After being dissolved in water, it can play the role of adsorption bridge and electric neutralization between particles at the same time to condense emulsified oil and colloid in wastewater and separate precipitation.It has excellent effect of oil removal, decolorization and COD reduction, and can complete the process of demulsification and coagulation at one time.The product is simple to operate, no need to repeat acid-base adjustment, can be directly treated, improve the treatment efficiency.Inorganic solidification flocculating agent integrates breaking glue, flocculating, settling and improving the solidification of mud layer to ensure cleaner water quality and dehydration effect of mud cake.

四、理现场图片 The scene pictures

|

|

|

金陵石化炼油厂处理现场

Treatment site of Jinling Petrochemical Refinery |

大港石化炼油厂处理现场

Dagang Petrochemical refinery treatment site |

|

|

|

大庆油田采油二厂处理现场

Treatment site of no.2 Oil recovery Plant in Daqing Oilfield |

大庆油田采油二厂南四联处理现场 Nansilian treatment site of the second oil production Plant in Daqing Oilfield |

南京莫尼亚离心机科技发展有限公司

联系人: 陈永欣 18013325617

徐锋 18013035617

售后服务: 赵士波 18013344029

电话/传真:025-58474011

邮箱: molniya@126.com

网址:www.njmoniya.cn

公司地址:江苏省南京市六合区竹镇工业园凌峰路71号

General Sales Agent for Iran, Iraq and Syria:

Company: ROYESH BEDONE MAX.LTD

Contact: Mr. GHASEM AMANI

Telephone number: 0098 912 111 2893

Mail box: robimaxfactory@gmail.com

- 手机版 莫尼亚 -